Understanding Print Settings When Ordering Parts: FDM and Resin parts

- Sep 7, 2025

- 4 min read

Updated: Oct 6, 2025

When ordering parts using our online ordering tool or by contacting us, you will need to specify a couple of settings based on your requirements. The very first and probably the most important thing is to choose the material for your parts. This will depend on your needs, and you can use our materials page to help you choose. If in doubt, don't hesitate to contact us directly.

Once you have decided on the material, there are a couple of settings you need to consider to order your parts. This article aims to provide a quick overview of what these settings mean.

Understanding 3D Printing Settings

FDM Printing

For FDM printing, you have two options to select: thickness and infill.

1. Thickness (a.k.a Layer Height): The Balance Between Detail and Speed

FDM printers build parts by depositing thin layers of plastic. The thickness or layer height is the height of each of these individual layers.

Depending on the material you are using, we have two thickness options:

200 microns (0.2mm) - Available for all materials

- This is by far the most common thickness setting.

- At this setting, layer lines are usually visible.

- This is optimal for print time and overall part cost.

100 microns (0.1mm) - Available for selected materials only

- At this layer height, individual layer lines are not usually visible unless you are looking very closely. This makes it a better option for parts where surface finish is the primary consideration.

- The downside of a smaller layer height is the significantly increased print time and cost, as the printer has to print double the number of layers.

Our recommended thickness setting is 200 microns for most parts, as it provides a good balance between cost and print quality. You may also come across a layer height of 300 microns being used in the industry. Traditionally, this has helped to reduce print time and cost. However, we find that with modern printers, going from 0.2mm layer height to 0.3mm does not really reduce printing time or cost but has the potential to reduce part strength.

2. Infill: How Strong Do You Need It?

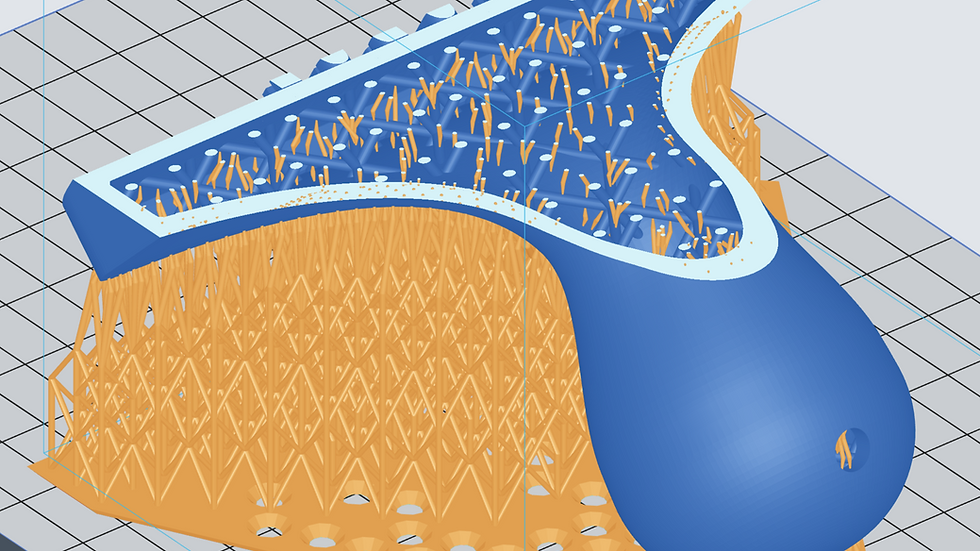

Your FDM 3D printed part is generally not 100% solid plastic on the inside. Instead, it's printed with an internal latticework called "infill." The infill density refers to how dense this internal structure is.

20% Infill - Low strength

- Best for: Most non-functional prototypes, visual models, and parts that don't need to withstand significant stress.

- Benefits: Faster printing, uses less material (more cost-effective).

- Expectation: OK structural integrity for general use.

50% Infill - Stronger, More Durable Parts

- Best for: Functional prototypes, mechanical components, and parts that will experience moderate loads or stress.

- Benefits: Significantly increased strength and rigidity compared to 20% infill.

- Expectation: Much more robust, but uses more material and takes longer to print.

80% Infill - Maximum Strength & Rigidity

- Best for: High-stress functional parts, jigs, fixtures, and components that require near-solid strength.

- Benefits: Close to maximum strength an FDM part can achieve.

- Expectation: Very strong and heavy, but the longest print time and highest material usage.

Resin (SLA) Prints

Resin 3D printing builds parts by curing liquid resin with light, resulting in incredibly high detail and smooth surfaces. The technology is fundamentally different from FDM, leading to different setting considerations.

All our resins have been optimised to give the best quality parts and are printed at a 50-micron layer height. For resin prints, infill works differently than FDM. Parts with thin walls and sections are generally printed solid. However, for parts with thick sections, it is often better to hollow out the part to improve print quality and reduce material usage. This is a manual process and also requires adding small holes into the part to allow for airflow during printing and to ensure all uncured resin is removed from the part during post-processing.

Choosing What's Right For You

Understanding these settings empowers you to better communicate your needs to us. Don't worry about being an expert – that's our job! We deliver high-quality 3D printed parts, and knowing your requirements will help us do that.

Do you have parts that you need 3D printed? Contact our Coventry team for a consultation or upload your model for a free quote.

Conclusion

In conclusion, selecting the right settings for your 3D printing project is crucial. The choices you make regarding thickness and infill can significantly impact the quality, strength, and cost of your final product. Whether you are opting for FDM or resin printing, understanding these parameters will help you achieve the best results.

If you have any questions or need assistance, feel free to reach out to us. We are here to help you navigate the world of 3D printing and ensure that you receive the best possible service.

_edit.png)